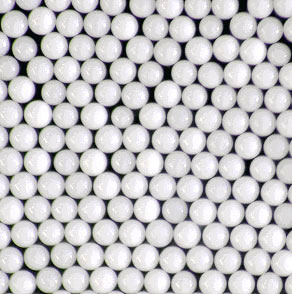

High purity alumina beads

The high purity alumina beads that we developed characterized in excellent abrasion resistance and high purity.

Feature

φ0.2mm

Excellent abrasion resistance

When the high hardness ceramics is ground, abrasion resistance is higher than the zirconia beads.

High purity

The purity of the alumina beads is 99.99% or more.

When grinding, no contamination other than alumina.

It is suitable for grinding and dispersion of the electronic material that dislikes mixing the radioisotope.

Excellent corrosion resistance

It is excellent in corrosion resistance to the acid and the alkali.

There is no performance deterioration to the warm water.

Energy saving of grinding and dispersion

The density of alumina is 2/3 of the zirconia, and the filling weight to the mill is 2/3.

In addition, there is a possibility that the consumption energy when grinding can be decreased.

Size of beads

φ0.1mm, φ0.2mm, φ0.3mm, φ0.4mm, φ0.5mm

Density

Apparent density : 3.9g⁄cm³

Filling density : 2.4g⁄cm³

Typical purity data

Typical purity data

| Typical purity data | Na | K | Si | Fe | Mg | Ca | Cr |

| Content (ppm) | 8 | 4 | 10 | 8 | 3 | 3 | 2 |

(U:4ppb or less, Th:5ppb or less)

Analysis by ICP

Abrasion resistant test

Comparison of amounts of beads abrasion when agitator beads mill is used

condition

Mill type : Agitator beads mill

Grinding material : α-alumina powder or aluminum hydroxide (Gibbsite)

Concentration of slurry : 60% in case of a-alumina powder, 15% in case of aluminum hydroxide

Rotor speed : 7.8m/s, 12.6m/s

Slurry temperature : 20 - 30℃

Test conditionA

Use slurry : No grinding material, only water

Rotor speed : 7.8m/s

Test conditionB

Use slurry : Alumina slurry of 60%

Rotor speed : 12.6m/s

Test conditionC

Use slurry : Aluminum hydroxide slurry of 15%

Rotor speed : 12.6m/s

Download

You need Adobe Reader in order to view the PDF files.

Contact us

For further information or any comments, please contact...

- TAIMEI CHEMICALS CO.,LTD. SALES OFFICE

-

- Address

- Maruito-GinzaBldg.9F, 1-3-9, Ginza, Chuo-ku, Tokyo 104-0061 Japan

MAP - info@taimei-chem.co.jp